How to Test & Control Concrete Moisture for Epoxy Resin Projects

Concrete moisture is one of the few possible hidden killers of an epoxy flooring project. If you've ever dealt with epoxy resin peeling , staining , and even mold growth - that's moisture. Whether its hygiene or adhesion, moisture can threaten the health and strength of your entire floors.

In this Xtreme Polishing Systems guide, we’ll delve into the causes of concrete moisture , effective testing methods, and solutions to ensure your epoxy flooring stands the test of time.

Moisture, Concrete, Epoxy: What You Need to Know

Concrete is naturally porous and prone to absorbing moisture from various sources.Whether it's moisture is from freshly poured concrete , or from groundwater, it needs to be treated before an epoxy installation. Luckily, moisture prevention & mitigation is incredibly easy to do!

Additionally, older concrete can absorb humidity from the environment. Over time, high levels of moisture trapped within concrete wreak havoc on an epoxy floor. Bubbling , discoloration , or even complete failure of the coating are all possible outcomes of moisture.

Concrete Moisture Testing Methods

Before applying epoxy , it’s crucial to assess the moisture levels in your concrete . As we said before, neglect to identify & treat the moisture trapped in concrete and you will later deal with variety of future epoxy problems. Here are some of the most effective testing methods:

- Moisture Meters: Non-invasive and easy to use, moisture meters provide a quick way to gauge the moisture content in concrete. However, they may not be as accurate for deeper moisture levels.

- Relative Humidity Testing: This method involves inserting sensors into the concrete to measure the internal humidity levels. It’s highly accurate , particularly in environments prone to high humidity. You'll need precision if you live in a high humidity area, or if you suspect more moisture than a surface test may present.

- Calcium Chloride Testing: This test measures the moisture emission rate by placing a calcium chloride container on the concrete . It's not as invasive as relative humidity testing, but still offers precise results.

Your mileage may vary when it comes to the needs of a moisture test, but we highly recommend the TRAMEX CME5 Moisture Meter for surface moisture, and relative humidity testing for deeper issues.

Concrete Moisture Mitigation Strategies for Epoxy Resin Installations

Moisture in concrete isn't new or secret. Luckily, our industry has spent years of research & development tackling this very issue. To safeguard your epoxy floor from moisture - related issues, consider the following solutions:

- Moisture Barriers: Applying a moisture barrier is one of the most effective ways to prevent moisture from seeping into the epoxy layer post-installation. These barriers act as a shield, blocking moisture from reaching the epoxy and ensuring long-lasting adhesion.

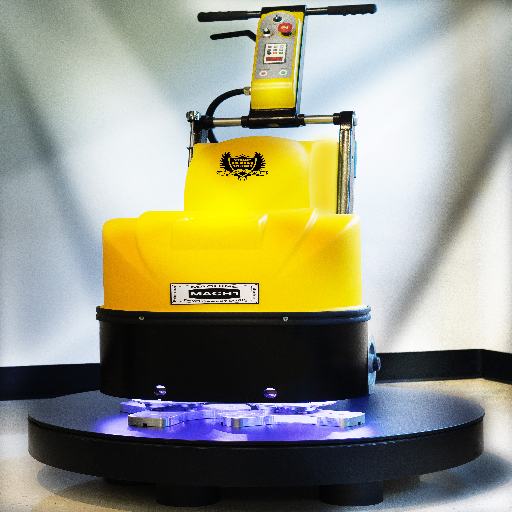

- Surface Preparation: Proper surface preparation is essential for a successful epoxy installation. Techniques such as shot blasting or diamond grinding not only ensure better adhesion, but also help in releasing trapped moisture within the concrete.

An effective moisture barrier paired with a high-quality epoxy resin are the perfect defense against moisture-related issues. And when you perform the necessary surface preparation , past, present & future moisture are all forgotten.

And don't forget - even during epoxy resin installations, you should still be mindful of ambient humidity seeping into the concrete .

Conclusion

Addressing concrete moisture is not just a step in the installation process, but a cornerstone of successful epoxy flooring projects. Identify, treat and mitigate sources of moisture, and you'll protect your floors against all these issues. Whether you use one test method or another, knowledge is the key to prevention. So don't neglect moisture in your next flooring project!

Xtreme Polishing Systems (XPS)

is your command center for all things concrete & epoxy flooring! Call our valuable team at (877) 958-5264

for any assistance with jobs or products. And our online store

is the best place to find quality materials at great prices!

You might also like