Polished Concrete Floors: Learn the Skills Behind the Shine

Behind every flawlessly polished surface lies a skilled installer who knows the ins and outs of the process. If you’ve ever asked yourself, “How do I do polished concrete floors?” then it may be time to take the next step in your career with hands-on training.

Learning how to polish concrete properly isn't just about running a grinder across a floor. It’s a detailed, step-by-step process that combines technical knowledge, surface preparation, and an understanding of chemical and mechanical applications.

That’s exactly what our 5-day training course delivers: real-world, hands-on experience with the tools, equipment, and techniques needed to master polished concrete flooring.

Why Choose Polished Concrete Floors?

Before diving into the training, it’s important to understand why polished concrete floors are so popular:

- Aesthetics: The smooth, reflective surface can be customized with various levels of gloss and decorative finishes.

- Durability: Highly resistant to wear, making it ideal for warehouses, showrooms, and garages.

- Low Maintenance: Unlike other flooring materials, polished concrete doesn’t require waxing or frequent resurfacing.

- Eco-Friendly: Utilizes the existing concrete slab and reduces waste, coatings, and additional materials.

These benefits make polished concrete a growing niche in the flooring industry—and a profitable one for those who know how to install it correctly.

What You’ll Learn in Our 5-Day Training Class

Our training class is designed to give you a comprehensive education on how to do polished concrete floors , from surface preparation to the final polish. Whether you're new to the industry or looking to expand your services, this class gives you both knowledge and confidence.

1. Understanding the Concrete Surface

You’ll begin by learning how to evaluate a concrete slab. You’ll assess:

- Concrete hardness

- Existing coatings or adhesives

- Cracks and imperfections

- Moisture content

Understanding the condition of the surface is key to successful polishing.

2. Surface Preparation Techniques

Surface prep is often the most important step in the entire process. We’ll cover:

- Grinding and profiling techniques

- Choosing the right diamond tooling

- How to use industrial vacuums and dust control systems

- Repairing cracks and patching damaged concrete

3. The Polishing Process

You’ll gain in-depth, hands-on experience with:

- Step-by-step grinding and polishing

- Progressing through different grits (from coarse to fine)

- Applying densifiers and sealers

- Achieving different finish levels (matte, semi-gloss, high-gloss)

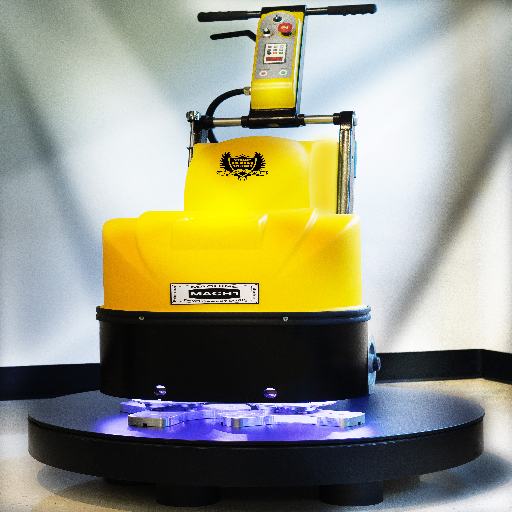

4. Equipment Training

Hands-on training with top-of-the-line equipment is a core part of our course. You'll use:

- Planetary grinders

- Edge grinders

- Industrial vacuum systems

- Burnishers and polishers

You'll also learn how to maintain your equipment to ensure longevity and performance on the job site.

5. Decorative Options and Advanced Techniques

Take your skills to the next level with decorative and custom finish techniques:

- Staining and dyeing concrete

- Creating patterns or logos

- Understanding guard products and burnishing techniques

Real-World Skills from Industry Pros

Our instructors are experienced professionals who have worked on high-profile polished concrete floor projects across the country. They provide honest, practical advice and walk you through the common mistakes and best practices in the field.

Topics like:

- Bidding and quoting polished concrete jobs

- Selecting the right products for each application

- Troubleshooting problems like uneven finishes or discoloration

- Time management and efficiency on job sites

You’ll walk away not only knowing how to do polished concrete floors , but how to deliver results that exceed client expectations.

Why Stay for the Full 5 Days?

We get this question a lot: "How much of the training do I really need before I can start?"

The answer is: stay for the full 5 days . Each day builds on the previous one, and by the end of the course, you'll have:

- Completed full start-to-finish polishing jobs

- Used every major piece of equipment

- Practiced fixing real-world challenges

- Built confidence in both your technical and business skills

Rushing through the training or leaving early means missing out on critical steps that can make or break your success on actual job sites.

South Florida Training Center

Located in beautiful South Florida , our training facility is fully equipped and designed to mimic real job site conditions. You'll work on large-format concrete floors, giving you a realistic experience that goes far beyond classroom learning.

We keep class sizes small to ensure personalized attention, and all participants receive a certificate of completion and ongoing support from our team.

Boost Your Business with Polished Concrete Services

Adding polished concrete floors to your service offerings can open up a whole new revenue stream. It allows you to:

- Expand into commercial and industrial markets

- Offer premium, high-value services

- Differentiate yourself from competitors

With polished concrete in high demand, now is the time to learn the skills that will keep your business competitive and future-proof.

Ready to Learn the Skills Behind the Shine?

Whether you're a contractor, installer, or business owner looking to expand your offerings, our 5-day polished concrete training class gives you the real-world experience and technical know-how to succeed.

Contact XPS today to reserve your spot in our next class. Let us help you take your polished concrete game to the next level—one flawless floor at a time.

You might also like