Epoxy Resin & Old Concrete: A Contractor’s Guide to Surface Renewal

Epoxy coatings are an excellent solution for rejuvenating old, worn concrete surfaces . But before applying epoxy , contractors need to follow a precise process to ensure long-lasting results. And you should consider if epoxy coating is the right solution for your floors!

In this guide, we’ll walk through the essential steps involved in preparing and applying epoxy on older concrete , while highlighting common challenges and solutions. We'll also discuss the considerations that factor into this decision.

Do I Need to Resurface or Refinish My Concrete?

Before any epoxy work begins, assessing the condition of the concrete is crucial. Older surfaces often suffer from cracks , pits , and unevenness . As a contractor, it’s important to thoroughly inspect the floor for any structural damage. This damage must be repaired to create a stable base for the epoxy.

Another critical factor to consider is moisture . Over time, older concrete may absorb water, which can interfere with the epoxy ’s adhesion. Moisture testing is essential , and using tools like moisture meters will help ensure the surface is dry enough to receive an epoxy coating. If moisture levels are too high, it could result in bubbles, delamination, or peeling post-installation.

Surface Preparation for Optimal Results

The key to any successful epoxy installation is surface preparation. Without it, even the best epoxy products will fail. Cleaning the surface is the first step. This involves removing all dirt, oil, and grease that could hinder epoxy adhesion . Industrial-grade cleaners and degreasers are typically used for this purpose.

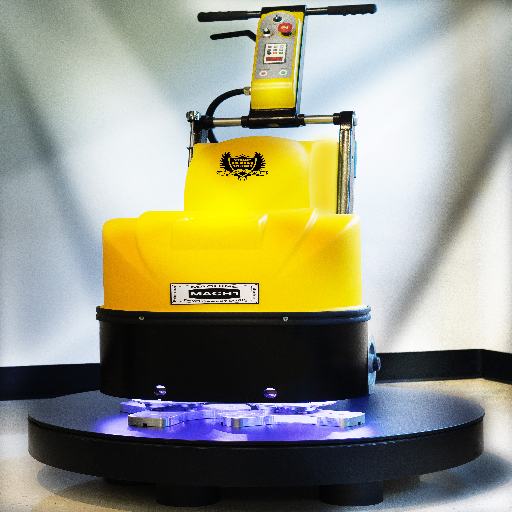

Next, concrete grinding or shot blasting will roughen the surface and create the ideal profile for epoxy adhesion . Contractors should aim for a Concrete Surface Profile (CSP) of 2 to 3 for most epoxy coatings. A rougher texture helps the epoxy bond securely to the concrete, ensuring a longer-lasting finish.

We recommend against the use of acid etching to complete this process. Though it's been an accepted solution for several years, recent research and experience reveals it's much less safe, efficient and effective than mechanical methods.

Repairing the Surface

If the old concrete has deep cracks or pits, these must be repaired before applying epoxy. Use high-quality patching compounds designed to work with epoxy . Once applied, repairs need to be cured fully and sanded down to create a level, seamless surface that is ready for coating.

If you're looking for a simple patch & repair concrete job , you can stop here. We feel obligated to warn you that this will only be pushing possible problems towards the future. But, if you're planning on a floor replacement in the near-term, that calculation may be fine.

Applying the Epoxy

With the surface prepared, it’s time to apply the epoxy coating. Contractors should choose an epoxy product specifically formulated for older concrete, ensuring maximum bonding strength. Start by applying a primer , which will enhance adhesion and help prevent air bubbles from forming during the topcoat application.

The primer, once cured, should be followed by the main epoxy coat while maintaining the evenness of the floor. Depending on the wear and tear of the old surface, additional coats may be necessary. Make sure each layer is fully cured before adding the next. Make sure you pick up high quality products so your floors stand the test of time!

We also recommend applying a final, strong topcoat once your main epoxy base has fully cured. This will help seal in your hard work for years to come!

Conclusion

Applying epoxy over old concrete can restore its durability, appearance, and functionality. By following proper surface preparation steps, addressing any underlying issues, and using the right epoxy products, contractors can ensure a high-quality, long-lasting finish. For the best results, always invest in quality materials and equipment to maximize the effectiveness of the epoxy coating!

Xtreme Polishing Systems (XPS)

is the command center for all things concrete & epoxy flooring! Our support team is on call at (877) 958-5264

for any product or job guidance. And our online store

is your one-stop-shop for high quality products at affordable rates!

You might also like